Alaabta

Qalabka wax-shiidka ee Hufan-sare ee Downhole

Qalabka Alaabta

Tusaale ahaan u soo qaado kabaha dhagaxa hoose ee fidsan:

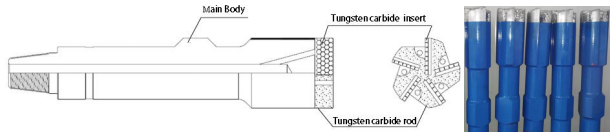

Jidhka ugu muhiimsan wuxuu qaataa birta daawaha ee waxqabadka sare leh (4145H) si loo hubiyo habsami u socodka iyo waxtarka leh ee hoos yimaada cadaadiska kala duwan ee qodista iyo xaalada xawaaraha wareega. Dhanka kale, waxaan qaadaneynaa mitirka tungsten carbide heer sare ah si aan u gaarno wax-shiidid degdeg ah. Xasijiye iyo goonnada bannaanka ee warshadda qashinka iyo taper-ka ayaa loo qaabayn karaa hadba baahida.

Gelida carbide Tungsten

·Superloy

Buuxiyaha wanaagsan ee qaraha, xargaha iyo mashiinnada taper.

Dib u fiican oo loogu talagalay miraha qashinka ah.

Cabirro ballaadhan oo la heli karo.

Inta ugu adag

Birta Muncher

Wax-u-dhaqso ka badan qalabka wax-shiidka ee caadiga ah.

Waxay yaraynaysaa cadaadiska loo baahan yahay marka wax lagu shubayo.

Waxay ka tagtaa jeexyo siman oo aan lahayn dibnaha si ay qashinka u laadlaadsanaadaan.

Waxay soo saartaa burbur leh cabbir la mid ah.

Goynta birta halkii aad shiidi lahayd.

· Opti-cut

Qashin yar yar.

Dhaqso badan ROP

Cimri dheer.

Cadaadiska hoose iyo shuruudaha qulqulka.

16 dhibcood oo gooyn ah iyo 8 geesood oo gooyn kasta oo gooyo.

Qaybta Alaabta

Warshada qashinka ee hoose/Balan/Blade

Waxaa loo isticmaalaa wax-shiididda, kootada, cabbirka dhexroorka, ilkaha qallafsan, tuubbada dhaqida, qalabka wax lagu qodayo, qalabka matoorka ceelka qoto dheer, baakadaha, qaybiyaha biyaha iyo qalabka kale ee qodista dheer.

Shidaalka qashinka ee Petrozhr waxaa lagu heli karaa qaabab kala duwan iyo joomatari. Injineernimadayada warshadeed ee horumarsan iyo alxanka khibrada leh waxay xaqiijinayaan qaab dhismeedka goynta joogtada ah oo waara ee warshad kasta oo junk ah.

Tab. 1 Flat/Concave/Blade Bottom junk parameter

| Ceel-biyoodka Dia. Dhererka lagu taliyay Mill Shoe OD (mm) (mm) Xadhkaha fur (mm) | PN fidsan | PN Concave | PN Daboolay |

| 95.2- 101.6 89 2-3 / 8REG 250 | JM089FX | JM089CX | JM089BX |

| 107.9- 114.3 97 2-3/8REG 250 | JM097FX | JM097CX | JM097BX |

| 117.5- 127 110 2-7/8REG 250 | JM110FX | JM110CX | JM110BX |

| 130- 139.7 121 2-7/8REG 250 | JM121FX | JM121CX | JM121BX |

| 142.9-152.4 130 2-7/8REG 250 | JM130FX | JM130CX | JM130BX |

| 155.6- 165. 1 140 3- 1/2REG 250 | JM140FX | JM140CX | JM140BX |

| 168- 187.3 156 3- 1/2REG 250 | JM156FX | JM156CX | JM156BX |

| 190.5-209.5 178 3- 1/2REG 250 | JM178FX | JM178CX | JM178BX |

| 212.7-241.3 200 4- 1/2REG 250 | JM200FX | JM200CX | JM200BX |

| 244.5-269.9 232 4- 1/2REG 250 | JM232FX | JM232CX | JM232BX |

| 273-295.3 257 6-5/8REG 250 | JM257FX | JM257CX | JM257BX |

| 298.5-317.5 279 6-5/8REG 250 | JM279FX | JM279CX | JM279BX |

| 320.6-346. 1 295 6-5/8REG 250 | JM295FX | JM295CX | JM295BX |

| 349.3-406.4 330 6-5/8REG 250 | JM330FX | JM330CX | JM330BX |

| 406.4-444.5 381 6-5/8REG 250 | JM381FX | JM381CX | JM381BX |

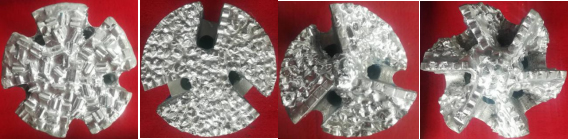

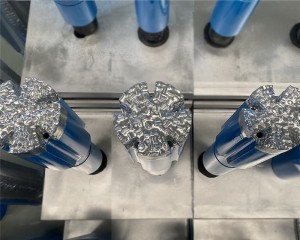

Kabaha Rotary

Kabaha wareega waxay ku qaataan walxaha carbide gudaha dhululubada si ay si wareeg ah u gooyaan dusha sare ee kalluunka aan caadiga ahayn, oo si tartiib tartiib ah u hagaajiyaan dusha sare ee kalluunka ee goobada, sida tuubooyinka, jirka daboolka, iwm.

[Fiiro gaar ah: Sababtoo ah dhexroorka iligga wax-shiidka gudaha ee kabaha rotart waa weyn yahay, wareegtada gadaaladu waa weyn tahay, markaa cadaadis hoose iyo qaab wareeg tartiib ah waa in lagu qaataa isticmaalka kabaha wareega. Guud ahaan, cadaadiska qodista waa inuusan dhaafin 10 KN xawaaraha wareegguna waa inuusan dhaafin 50 r/min.]

Nooca A

Jar birta, sibidhka iyo samaynta.

Goynta OD iyo hoose.

Nooca B

Goynta birta halka nadiifinta ay yar tahay.

Goynta aqoonsiga iyo hoose.

Nooca C

Sameynta gooyay.

Goynta OD iyo hoose.

Nooca D

Iska yaree samaynta iyo kalluunka isku mar.

Goynta aqoonsiga, OD iyo hoose.

Tab.2 Qiyaasta kabaha Rotary

| Casing/Wellbore Dia. | Kabaha Rotary OD (mm) | Kabaha Rotary Dhererka (mm) | Talo-soo-jeedin Xariif ah | PN Kabaha Rotary | |

| 4in | 101.6mm | 95 400 | FJWP | TXX095 | |

| 5- 1/2in | 139.7mm | 114 500 | FJWP | TXX114 | |

| 5-3/8in | 146.05mm | 118 500 | FJWP | TXX118 | |

| 6-5/8in | 168.28mm | 136 425 | FJWP | TXX135 | |

| 7in | 177.8mm | 152 450 | FJWP | TXX152 | |

| 7-5/8in | 193.68mm | 160 450 | FJWP | TXX160 | |

| 8-5/8in | 219.1mm | 185 550 | FJWP | TXX185 | |

| 12- 1/4 gudaha 311. 15mm | 203 450 | FJWP | TXX203 | ||

| 15-5/8 gudaha 396.88mm | 298 450 | FJWP | TXX298 | ||

| 20in | 508mm | 406 450 | FJWP | TXX406 | |

Taper Mill

Mashiinnada Taper-ka waxay dib u soo celiyaan xannibaado, daasadaha burburay iyo qaybaha liner-ka iyo daaqadaha firileyda iyo daasadaha. Cidhifka hoose ee mashiinka tuubada, oo yar, dhexroorkiisu wuxuu galayaa daaskii dumay iyo khadadka. Dabadeed geesaha reamer-ka yara wareegaya si ay qaybta hoose u buuxiso. dhexroorka-shiidka.

Mashiinnada Taper-ka waxay ka kooban yihiin jir koone ah iyo carbide tungsten. Taper-ka jidhku waa 30 darajo, koofiyaddu waa baalal-qaabeeya, oogada sare waa mid adag ama dhex gelinaysa carbide tungsten.

Tab.3 Halbeeg-beegtida dhagax-shiidka

| Ceel biyood Dia. Taper warshad OD Lagu taliyay Dhererka (mm) (mm)Isku dhufashada Dulqaad(mm) | P.N. Taper warshad | ||

| 95- 101.6 | 89 | 2-3/8REG 300 | XZ089 |

| 107.9- 114.3 97 2-3/8REG 300 | XZ097 | ||

| 117.5- 127.0 110 2-7/8REG 300 | XZ110 | ||

| 130- 139.7 121 2-7/8REG 300 | XZ121 | ||

| 142.9- 152.4 130 2-7/8REG 300 | XZ130 | ||

| 155.6- 165. 1 140 3- 1/2REG 300 | XZ140 | ||

| 168- 187.3 156 3- 1/2REG 300 | XZ156 | ||

| 190.5-209.5 178 3- 1/2REG 300 | XZ178 | ||

| 212.7-241.3 200 4- 1/2REG 300 | XZ200 | ||

| 244.5-269.9 232 6-5/8REG 350 | XZ232 | ||

| 273-295.3 257 6-5/8REG 350 | XZ257 | ||

| 298.5-317.5 279 6-5/8REG 350 | XZ279 | ||

| 320.6-346. 1 295 6-5/8REG 350 | XZ295 | ||

| 349.3-406.4 330 6-5/8REG 350 | XZ330 | ||

| 406.4-444.5 381 6-5/8REG 350 | XZ381 | ||

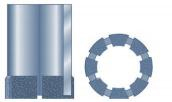

Qaraha String Mill

Kabaha xarigga qaraha waa mid ka mid ah qalabka wax lagu shiido ee hawsha dhinac-istaagga. Waxa loo isticmaalaa hagaajinta daaska, reaming iyo furitaanka kanaalada. Caadi ahaan waxa la isticmaalaa isla markiiba ka dib marka la furo daaqadaha. Cidhifka wax-shiidka (aagga shaqada) ee warshadda qaraha waxay la xiriirtaa darbiga ceelka riigga ah, iyo dhammaadka cidhif kasta waxaa loo qaabeeyey sidii kolay. Marka daaqada la furayo, mishiinka qaraha ayaa ka dheerayn kara daaqada xagga sare oo ka saari kara qolofta iyo daacinta ku hadhay gidaarka tuubada inta lagu jiro goynta hore.

Tab.4 Halbeeg-beegtida xadhkaha qaraha

| Ceel-biyoodka Dia. Maroojiska (mm/in) Xargaha | Goobta shaqada OD (mm/in) | Dhererka Goobta Shaqada (mm/in) | Dhererka Totul (mm/in) | PN |

| 139.7 (5- 1/2) NC 26 112 (4-7/ 16) 600 (23-5/8) | 1130 (44) | XGMX112 | ||

| 139.7 (5- 1/2) NC 26 116 (4-9/ 16) 600 (23-5/8) | 1130 (44) | XGMX116 | ||

| 139.7 (5- 1/2) NC 26 118 (4-5/8) 600 (23-5/8) | 1130 (44) | XGMX118 | ||

| 139.7 (5- 1/2) NC 31 120 (4-3/4) 600 (23-5/8) | 1280 (50) | XGMX120 | ||

| 146.0 (5-3/4) NC 31 124 (4-7/8) 600 (23-5/8) | 1280 (50) | XGMX124 | ||

| 168.3 (6-5/8) NC 31 142 (5-9/ 16) 600 (23-5/8) | 1280 (50) | XGMX142 | ||

| 177.8 (7) NC 31 151 (5- 15/ 16) 600 (23-5/8) | 1280 (50) | XGMX151 | ||

Mashiinka duuliyaha

Mashiinnada tijaabada ah waxaa loogu talagalay in lagu shubo daasadaha, lineer-ka, kabaha wareega ama tuubooyinka aqoonsiga ee waaweyn. Mashiinnada goynta ee lagu labisan yahay walxo carbide tungsten ah oo heersare ah ayaa ka dhigaya warshadda duuliyaha ee Petrozhr waxay gaari kartaa dhexgalka degdega ah iyada oo ay weheliso xidhid aad u yar. Dhamaadka tijaabada waxaa loo isticmaalaa in lagu dejiyo aqoonsiga shayga la shiiday.

Tab.5 Halbeeg-beegtida duuliyaha

| Ceel biyood Dia. (mm) | Isku dhufashada Dulqaad | Goobta shaqada OD (mm) | Dhererka daabka goynta (mm) | Dhererka aagga tijaabada (mm) | PN |

| 153 2 3/8REG | 130 200 | ≧45 | LYMX130 | ||

| 165 2 3/8REG | 140 200 | ≧45 | LYMX140 | ||

| 187 3 1/2REG | 156 200 | ≧55 | LYMX156 | ||

| 210 4 1/2REG | 178 200 | ≧55 | LYMX178 | ||

| 241 4 1/2REG | 200 200 | ≧55 | LYMX200 | ||

| 270 4 1/2REG | 232 200 | ≧55 | LYMX232 | ||

| 295 6 5/8REG | 257 250 | ≧55 | LYMX257 | ||

| 317 6 5/8REG | 279 250 | ≧55 | LYMX279 | ||

| 346 6 5/8REG | 295 300 | ≧55 | LYMX295 | ||

| 406 6 5/8REG | 330 300 | ≧55 | LYMX330 | ||

| 445 6 5/8REG | 331 300 | ≧55 | LYMX331 | ||

Shaxda codsiga Tungsten carbide

| Codsiga lagu taliyay | Superloy | Opti-cut | Bir-duqaha | Bir-duqaha oo leh Superloy |

| Qubayska dalool furan | √ | √ | ||

| Dhuumaha daloolida dhaqida | √ | |||

| Xirmada quruurux-dhaqashada | √ | √ | ||

| Goynta xadhkaha wax lagu dhaqo | √ | |||

| Baakadaha wax lagu dhaqo | √ | |||

| shiidida Poil | √ | |||

| Shidida qashinka dabacsan | √ | √ | ||

| Baakadaha taagan ama tuubada ama tuubada qashinka lagu shubo | √ | |||

| shiidid qaraha | √ | |||

| Xarig-shiidid | √ |

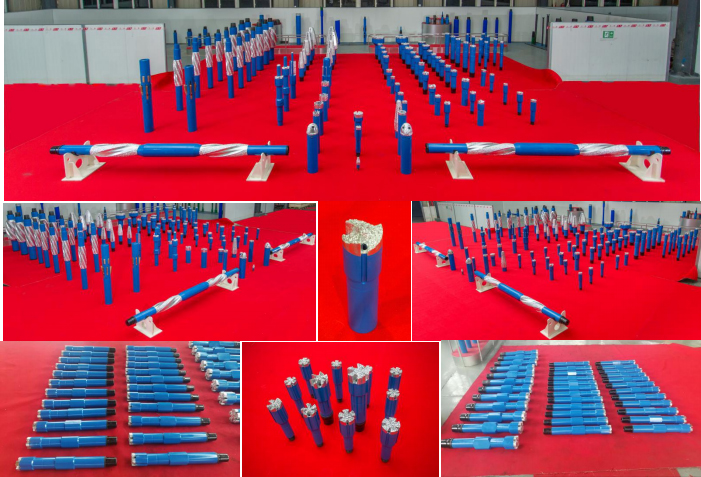

Sawirada Shayga Kalluumeysiga

Qolka 703 Dhismaha B, Xarunta Greenland, aagga horumarinta Hi-tech Xi'an, Shiinaha

Qolka 703 Dhismaha B, Xarunta Greenland, aagga horumarinta Hi-tech Xi'an, Shiinaha 86-13609153141

86-13609153141